Unlike other subsea flow metering technologies, the Solartron ISA multiphase wet gas flowmeters do not have retrievable electronics. There is a very advantageous reason for this.

Retrieving any equipment that is subsea, is both expensive, risky and requires additional complexity in design to allow retrievability which adds cost. If a subsea electronics module for a flowmeter needs replacement, production and hydrocarbon revenue will be delayed and significant costs will be incurred in retrieving and redeploying the equipment.

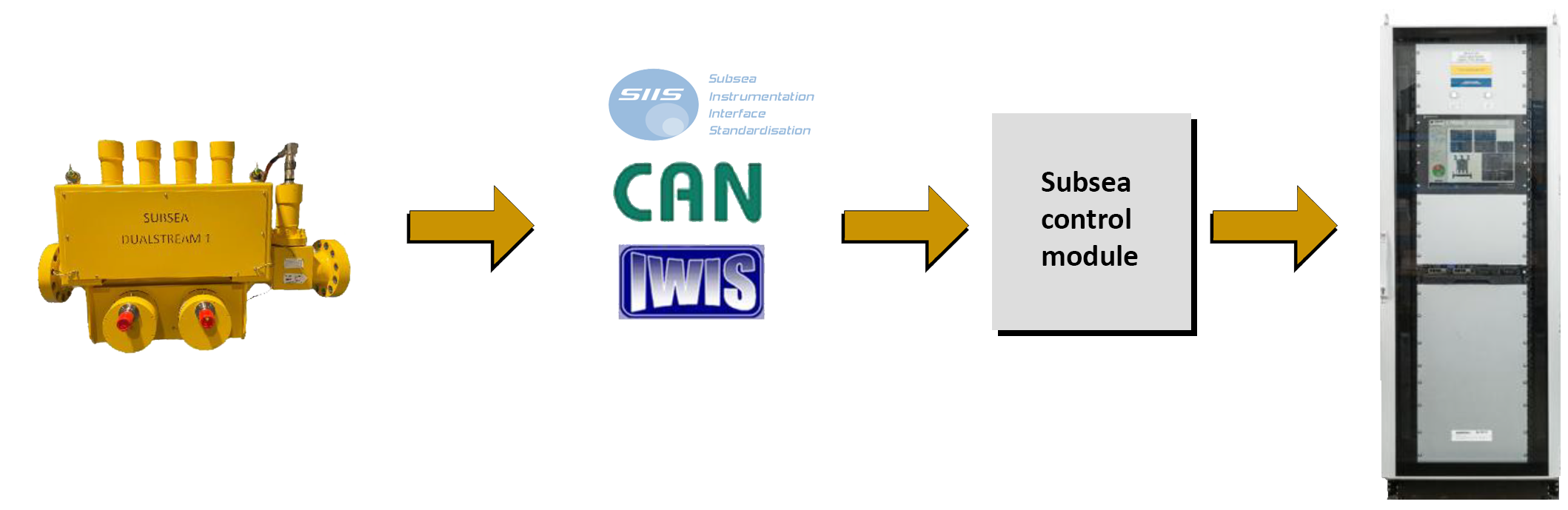

In many other manufacturers complex multiphase flow meters, communications bandwidth limits data transfer to the surface and therefore local [to the flowmeter] high-speed processing of radioactive or dielectric signals is essential. Solartron ISA’s philosophy has been to keep subsea hardware and sensors as simple and robust as possible and to carry out processing of flow meter raw data either topside in the platform control room or in some instances onshore. This removes the need for having an electronics module subsea entirely. Solartron ISA supplies redundant measurement sensors as a back up to individual sensor failure.